The Facts About Welders Near Me Uncovered

Wiki Article

Fascination About Cold Welding

Table of ContentsThings about Mig WelderThe Basic Principles Of Mig Welder The smart Trick of Welding Shops Near Me That Nobody is Talking AboutEverything about Welding TableNot known Facts About Spot WelderFacts About Mig Welder RevealedUnderwater Welding for Beginners

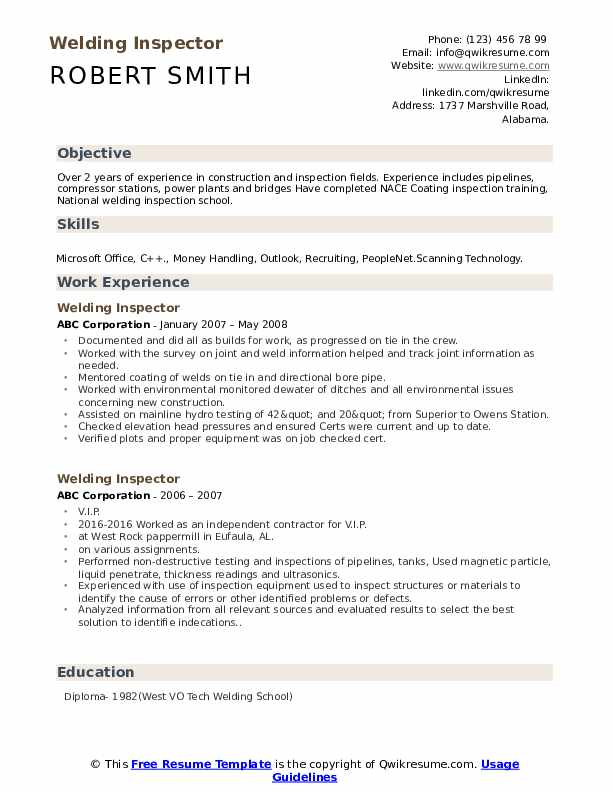

Examiners gauge welded products to make sure that they fulfill requirements for dimension. The accredited weld assessor utilizes anxiety tools to place stress and anxiety on weld joints.Assessors likewise inspect weld device arrangement as well as the welding techniques of welders on operate in progress to ensure the quality of the work. Welding inspectors tape the results of examinations and welding evaluations. Credentials, Companies may call for a secondary school education for a certified welder setting. An university education is not required for the majority of welding or welding examination positions, but an associate level in welding technology can enhance the chances of landing a task.

Automation does not minimize the requirement for assessment.

Something failed. Wait a moment and try again Try once again.

The 6-Minute Rule for Mig Welder

Senior Personnel Designer, National Board This article was originally released in the Loss 2009 National Board BULLETIN as the initial of a two-part series. Please see Standard Weld Assessment - Component 2 for the final thought of this post. Note: The objective of this short article is to supply assessors with a basic understanding of weld inspection.While not imperative, the examiner ought to find out to check out common weld icons such as the AWS icons. At the minimum, the inspector must always lug a recommendation guide to interpret weld signs. Having assessed all this details beforehand, the assessor will be prepared to identify any type of issues as they create as opposed to after-the-fact.

The maker or repair organization (certificate holder) has actually shown on duty drawing that a weld joint is to be prepared with a 60-degree bevel and also root void of 1/16 inch. Unless the bevels are crushed on precision machinery, it is skeptical they will achieve a specific 60-degree bevel as suggested.

The nozzle axis is 90 to the level head, as well as the attachment weld includes a 3/8-inch fillet weld. The assessor can conveniently determine the fillet weld to make sure conformity. Now, let's set up the very same nozzle in a tiny diameter vessel shell (Fig. 2). The fillet weld will have a tendency to spread or squash on contrary sides of the nozzle as a result of the curvature of the shell.

Unknown Facts About Mig Welder

This example ends up being much more essential if the nozzle is set up at an angle besides 90 (Fig. 3). Utilizing the same nozzle add-on instance as explained above, allow's look at the weld joint prep work. The certification holder has defined a 45-degree bevel around the area of the opening in the flat head and also the vessel covering.4). The bent covering will present even more of a difficulty. The inspector will certainly have to figure out if the certificate owner is referencing the bevel from the vertical axis of the nozzle (Fig. 5) or from the variable reference aircraft of the rounded covering (Fig. 6). When bevels are prepared with a cutting lantern and ended up with a grinder, it is really tough to maintain a specific angle.

Inspectors are trained to think just what their eyes tell them; however when the assessor can not see the inner surface area of the tube, it comes to her latest blog be challenging to approve that scenario. If the tube ends are correctly prepared (beveled) as well as a certified welder is using a certified welding procedure, the chances are very excellent that the welds will certainly be complete penetration.

One "red flag" to a potential problem would be if the examiner observes that the tube ends have not been beveled. The examiner must immediately ask the certificate holder about this situation. It might be as easy as the certificate owner having simply not executed that navigate here action in the procedure yet, or maybe as negative as his/her having tried to save money and time by not beveling completions.

Some Known Factual Statements About Welders Near Me

The welder would need to begin with a huge origin space and afterwards be very cautious not to "press via" excess filler steel to trigger weld accumulation on the within of the tube.1, condition 6. 1, calls for welding examiners of all levels to pass an eye assessment, with or without corrective lenses, to prove near vision skill, in at the very least one eye, on Jaeger J2 letters or smaller at a range not less than 12 inches. A shade understanding test and also a contrast differentiation tones of gray examination need to be taken, however the employer develops the acceptance for these 2 tests based upon the weld assessment being carried out.

That's where "Mr.

See This Report on Mig Welder

He told the examiner he needed to rush up as well as leave our means the same way a drill sergeant would tell a new recruit to come down and do pushups! The examiner really did not say a word; he just nodded and walked off. The next early morning when we reached the work there was a sea of red throughout the flooring we were working with.

Our welding assessor was not a satisfied camper. The good news is for us, we were able to speak to the examiner and explain what an idiot our employer was as well as that he was not talking for our team.

The Basic Principles Of Underwater Welding

Influence test. Etching. Devastating are typically made use of in educational screening, shop testing, and also examinations welders take to obtain accredited or worked with on at a jobsite.The tasks are divided into 3 major phases; Verify that the product remains in accordance with drawing/ WPS recognized and traced to an examination certificate in appropriate problem (free from damages and also contamination) WPS is approved and readily available to welders (and also inspectors). Welding devices remains in ideal condition and calibrated as ideal.

Identification of welders certification for every WPS to be made use of and also all welder qualification certificates stand. Welding consumables to be made use of are-as defined by the WPS-stored/controlled as specified by the QC treatment. Joint fit-ups are in conformity with WPS/ illustrations Tack welds are appropriate per criteria, code or WPS.

The minimum temperature for Preheat (if needed) remains in conformity with WPS. Make certain climate condition appropriate/ adhere to Code (conditions will not affect welding) when on-site/ field welding. Welding process should be in accordance with WPS. Preheat (if required) minimum temperature is being maintained according to WPS.

Not known Facts About Underwater Welding

Guarantee all reports/records are completed and also looked at as called for. Recommendation: Inspector Responsibilities By Neal Chapman CSWIP 3. welding shops near me. 1 Course note.Report this wiki page